Njengoba ubuchwepheshe be-laser enamandla amakhulu buqhubeka nokuthuthuka ngokushesha, ama-Laser Diode Bars (ama-LDB) asetshenziswa kabanzi ekucubungulweni kwezimboni, ekuhlinzeni kwezokwelapha, e-LiDAR, kanye nasekucwaningweni kwesayensi ngenxa yobuningi bawo bamandla aphezulu kanye nokukhishwa kokukhanya okuphezulu. Kodwa-ke, ngokuhlanganiswa okwandayo kanye nogesi osebenzayo wama-laser chips, izinselele zokuphathwa kokushisa ziya ngokuya zigqama—zithinta ngqo ukuzinza kokusebenza kanye nesikhathi sokuphila kwe-laser.

Phakathi kwamasu ahlukahlukene okuphatha ukushisa, i-Contact Conduction Cooling ivelele njengenye yezindlela ezibaluleke kakhulu futhi ezamukelwa kabanzi ekupakisheni ibha ye-laser diode, ngenxa yesakhiwo sayo esilula kanye nokuqhuba okuphezulu kokushisa. Lesi sihloko sihlola izimiso, izinto ezibalulekile ezicatshangelwayo zokuklama, ukukhethwa kwezinto, kanye nezitayela zesikhathi esizayo zale "ndlela ezolile" yokulawula ukushisa.

1. Izimiso Zokupholisa Ukuxhumana Kokuxhumana

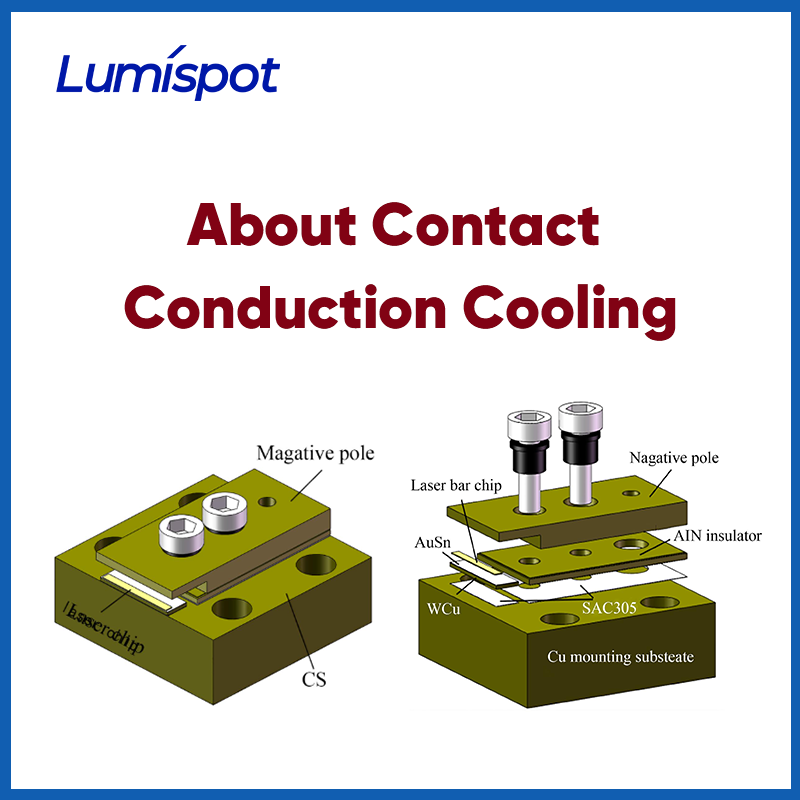

Njengoba igama lisikisela, ukupholisa kokuqhuba kokuxhumana kusebenza ngokusungula ukuxhumana okuqondile phakathi kwe-laser chip kanye nesinki yokushisa, okuvumela ukudluliselwa kokushisa okuphumelelayo ngezinto zokuqhuba kokushisa okuphezulu kanye nokusabalala okusheshayo endaweni yangaphandle.

①The HdlaPi-ath:

Kubha ejwayelekile ye-laser diode, indlela yokushisa imi kanje:

I-Chip → Isendlalelo Sokusonga → I-Submount (isb., ithusi noma i-ceramic) → I-TEC (I-Thermoelectric Cooler) noma i-Heat Sink → Indawo Ezungezile

②Izici:

Le ndlela yokupholisa inezici ezilandelayo:

Ukugeleza kokushisa okugxilile kanye nendlela emfushane yokushisa, kunciphisa ngempumelelo izinga lokushisa le-junction; Idizayini encane, efanele ukupakishwa okuncane; Ukuhanjiswa okungasebenzi, okungadingi izihibe zokupholisa ezisebenzayo eziyinkimbinkimbi.

2. Izinto Ezibalulekile Okufanele Uzicabangele Ngomklamo Wokusebenza Kokushisa

Ukuqinisekisa ukupholisa okuphumelelayo kokuhanjiswa kokuxhumana, izici ezilandelayo kumele zibhekwe ngokucophelela ngesikhathi sokuklama idivayisi:

① Ukumelana Nokushisa Ku-Solder Interface

Ukushisa kwesendlalelo se-solder kudlala indima ebalulekile ekumelaneni nokushisa okuphelele. Izinsimbi ezisebenza ngokushisa okuphezulu njenge-AuSn alloy noma i-indium emsulwa kufanele zisetshenziswe, futhi ubukhulu besendlalelo se-solder kanye nokufana kufanele kulawulwe ukuze kuncishiswe izithiyo zokushisa.

② Ukukhetha Izinto Ezingaphansi Kokukhweza

Izinto ezivamile zokufaka ngaphansi komhlaba zifaka:

Ithusi (Cu): Ukushisa okuphezulu, kuyabiza kakhulu;

Ithusi le-Tungsten (WCu)/ithusi le-Molybdenum (MoCu): Ihambisana kangcono ne-CTE nama-chips, inikeza kokubili amandla kanye nokuqhuba;

I-Aluminium Nitride (AlN): Ukushisa okuhle kakhulu kukagesi, okufanele ukusetshenziswa kwamandla aphezulu.

③ Ikhwalithi Yokuthintana Komphezulu

Ukungaguquguquki komphezulu, ukuba yisicaba, kanye nokumanzi kuthinta ngqo ukusebenza kahle kokudlulisa ukushisa. Ukupholisha kanye nokufakwa kwegolide kuvame ukusetshenziselwa ukuthuthukisa ukusebenza kokuthintana nokushisa.

④ Ukunciphisa Indlela Yokushisa

Umklamo wesakhiwo kufanele uhlose ukufinyeza indlela yokushisa phakathi kwe-chip kanye nesinki yokushisa. Gwema izendlalelo zezinto eziphakathi ezingadingekile ukuze uthuthukise ukusebenza kahle kokushabalalisa ukushisa.

3. Iziqondiso Zokuthuthukiswa Kwesikhathi Esizayo

Njengoba kuqhubeka ukuthambekela kokwenza izinto zibe zincane kanye nobuningi bamandla aphezulu, ubuchwepheshe bokupholisa ukuhanjiswa kokuxhumana bushintsha ngezindlela ezilandelayo:

① Ama-TIM Ahlanganisiwe Anezingqimba Eziningi

Ukuhlanganisa ukuqhutshwa kokushisa kwensimbi kanye ne-flexible buffering ukuze kuncishiswe ukumelana kwe-interface futhi kuthuthukiswe ukuqina kokujikeleza kokushisa.

② Ukupakisha Okuhlanganisiwe Kokusinki Wokushisa

Ukuklama ama-submount nama-heat sink njengesakhiwo esisodwa esihlanganisiwe ukuze kuncishiswe ukuxhumana kwe-contact kanye nokwandisa ukusebenza kahle kokudlulisa ukushisa ezingeni lesistimu.

③ Ukuthuthukiswa Kwesakhiwo Se-Bionic

Ukusebenzisa izindawo ezakhiwe nge-microstructure ezilingisa izindlela zemvelo zokusabalalisa ukushisa—njengokuqhutshwa kokushisa okufana nokwesihlahla noma “amaphethini afana nesikali”—ukuthuthukisa ukusebenza kokushisa.

④ Ukulawula Okushisayo Okuhlakaniphile

Kufaka izinzwa zokushisa kanye nokulawula amandla aguqukayo kokuphathwa kokushisa okuguquguqukayo, okwandisa impilo yokusebenza kwedivayisi.

4. Isiphetho

Kumabha e-laser diode anamandla aphezulu, ukuphathwa kokushisa akuyona nje inselele yobuchwepheshe—kuyisisekelo esibalulekile sokuthembeka. Ukupholisa kokuxhumana, ngezici zako ezisebenzayo, ezivuthiwe, nezingabizi kakhulu, kusalokhu kungenye yezixazululo eziyinhloko zokushabalalisa ukushisa namuhla.

5. Mayelana Nathi

Kwa-Lumispot, siletha ubuchwepheshe obujulile ekupakisheni i-laser diode, ukuhlolwa kokuphathwa kokushisa, kanye nokukhetha izinto. Umgomo wethu ukuhlinzeka ngezixazululo ze-laser ezisebenza kahle kakhulu, ezihlala isikhathi eside ezilungiselelwe izidingo zakho zohlelo lokusebenza. Uma ungathanda ukufunda kabanzi, sikwamukela ngemfudumalo ukuthi uxhumane nethimba lethu.

Isikhathi sokuthunyelwe: Juni-23-2025