Ezinhlelweni zokusebenza ezifana nama-laser anamandla aphezulu, amadivayisi kagesi anamandla, kanye nezinhlelo zokuxhumana, ukwanda kokusetshenziswa kwamandla kanye namazinga okuhlanganisa kwenze ukuphathwa kokushisa kwaba yinto ebalulekile ethinta ukusebenza komkhiqizo, isikhathi sokuphila, kanye nokuthembeka. Kanye nokupholisa kweziteshi ezincane,ukupholisa kwesiteshi esikhuluisivele njengesixazululo esisebenzayo sokupholisa uketshezi. Isakhiwo sayo esilula, izindleko eziphansi, kanye nokugcinwa okulula kwenza ifaneleke kakhulu ezimweni eziningi zezimboni.

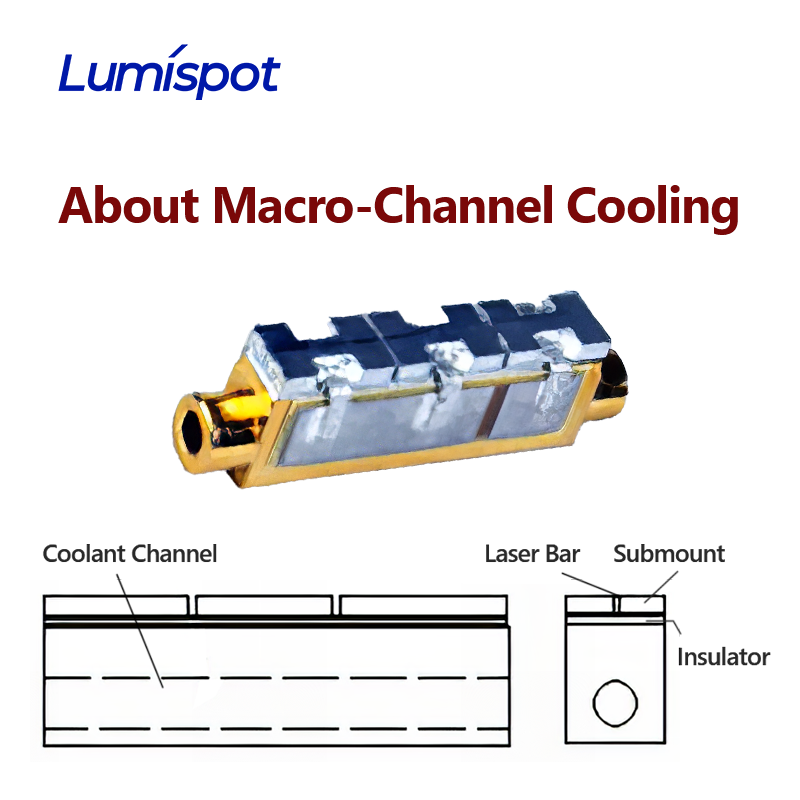

1. Kuyini Ukupholisa Iziteshi Ezinkulu?

Ukupholisa kweziteshi ezinkulu kuhilela ukusetshenziswa kweziteshi ezinkulu zokugeleza kwe-coolant (ngokuvamile ebangeni lamamilimitha) ezakhiwe emapuletini noma kumamojula okupholisa. Lezi ziteshi ziqondisa uketshezi lwe-coolant—amanzi avame ukuba yi-deionized, izixazululo ezisekelwe ku-glycol, noma ezinye izinto ezipholile zezimboni—ngohlelo ukuze kususwe ukushisa okukhiqizwa ngesikhathi sokusebenza kwedivayisi. Uma kuhlanganiswe ne-loop yokupholisa amanzi, lokhu kusetha kwenza kube lula ukulawula ukushisa okuqhubekayo nokusebenzayo.

2. Isiteshi Se-Macro vs. Isiteshi Se-Micro: Umehluko Obalulekile

| Isici | Ukupholisa Iziteshi Ezinkulu | Ukupholisa Iziteshi Ezincane |

| Usayizi Wesiteshi | Isikali semilimitha (1mm kuya kumamilimitha amaningana) | Isikali se-Micrometer (amashumi kuya kwamakhulu e-μm) |

| Ubunzima Bokukhiqiza | Kuphansi kakhulu | Kudinga imishini enembile kakhulu |

| Ukumelana Nokugeleza | Uketshezi oluphansi, lugeleza kalula | Kuphezulu, kudinga umfutho ophezulu wephampu |

| Ukusebenza Kahle Kokushintshana Kokushisa | Okumaphakathi, okufanelekela ukushisa okuphakathi | Phezulu, kulungele ukushisa okukhulu |

| Izindleko | Ngaphansi | Okuphakeme |

| Isicelo Esijwayelekile | Izinhlelo zokushisa eziphakathi kuya kweziphansi, ezinokwethenjelwa okuphezulu | Ubuningi bamandla aphezulu, imithombo yokushisa yendawo |

3. Izinzuzo Zokupholisa Iziteshi Ezinkulu

Nakuba ukusebenza kwayo kahle kokushisa kuphansi kunezixazululo zeziteshi ezincane, ukupholisa iziteshi ezinkulu kunikeza izinzuzo eziningana eziphawulekayo:

①Ukuthembeka okuphezulu:

Iziteshi ezibanzi azivami kakhulu ukuvaleka, zinikeza ukuzinza okuhle kwesikhathi eside—okufanelekile ekusebenzeni okuqhubekayo kwezimboni.

②Izindleko zokukhiqiza eziphansi:

Isakhiwo esilula kanye nezinketho ezahlukene zokwenziwa kwenza kube kuhle ukukhiqizwa ngobuningi.

③Kulula ukunakekela:

Izikhawu ezinde zokuhlanza, izindleko zokulungisa eziphansi, kanye nezidingo zokuhlanza ama-coolant eziqinile.

④Umthamo wokupholisa owanele:

Kumadivayisi anokushisa okuphakathi nendawo, ukupholisa kwesiteshi esikhulu kugcina amazinga okushisa afanele okusebenza futhi kwandise isikhathi sokuphila kwedivayisi.

4. Izimo Zokusebenza

Ukupholisa iziteshi ezinkulu kusetshenziswa kabanzi kulezi zindawo ezilandelayo:

①Amamojula e-laser:

Ikakhulukazi kuma-laser aphakathi kuya kwaphansi noma ama-laser emodi ye-CW, izinhlelo ze-macro-channel zingaphatha kalula umthwalo wokushisa.

②Amamojula kagesi kagesi:

Njengezilungisi, iziguquli ze-DC-DC, kanye namamojula e-IGBT.

③Ama-amplifier kagesi ezinhlelweni zokuxhumana kanye ne-radar:

Ilungele izindawo eziyinkimbinkimbi ezidinga ukusebenza isikhathi eside futhi okuzinzile.

④Izinhlelo zokupholisa emishinini yezokwelapha neyezimboni:

Kufaka phakathi amadivayisi okwelapha nge-laser ye-semiconductor, imishini yokumaka nge-laser, nokuningi.

5. Izinto Ezibalulekile Okufanele Uzicabangele Ngokuklama Kokupholisa Iziteshi Ezinkulu

Isixazululo sokupholisa esiphumelelayo se-macro-channel sidinga ukunakwa kulezi zici ezilandelayo:

①Isakhiwo sesiteshi:

Kufanele kulungiselelwe ngokusekelwe ekusabalalisweni komthombo wokushisa wedivayisi ukuze kufezwe ukupholisa okufanayo.

②Ukukhetha izinto:

I-Copper, insimbi engagqwali, noma i-aluminium alloys zivame ukusetshenziswa ngenxa yokushisa okuphezulu kanye nokumelana nokugqwala.

③Izinga lokugeleza kanye nokuhambisana kwephampu:

Ukwakheka kahle kwesivinini soketshezi kanye nokugeleza kwe-coolant kuqinisekisa ukushintshaniswa kokushisa okuphumelelayo kanye nokuqina kwesistimu.

④Izixhumi ezijwayelekile:

Ivumela ukuhlanganiswa okulula kumadivayisi noma amamojula amakhasimende.

6. Isiphetho

Ukupholisa iziteshi ezinkulu kuyaqhubeka nokudlala indima ebalulekile ekusetshenzisweni kwezimboni ngenxa yobulula bayo, ukuthembeka, kanye nokulula kokugcinwa. Kuyisisombululo esingabizi futhi esithembekile, ikakhulukazi ezinhlelweni ezinobuningi bokushisa obuphakathi kuya phansi. Njengoba ukwakheka kwedivayisi kuthuthuka, izixazululo zeziteshi ezinkulu nazo ziyathuthukela ekuhlanganisweni okuphezulu kanye nokuzivumelanisa nezimo okuthuthukisiwe.

7. Mayelana NATHI

I-Lumispotinikeza ubuchwepheshe obubanzi kuzo zombili izixazululo zokuphathwa kokushisa kwesiteshi esikhulu kanye nesiteshi esincane. Sihlinzeka ngamamojula okupholisa enziwe ngokwezifiso ama-laser, amadivayisi e-optoelectronic, ama-electronics kagesi, nokuningi. Ukugxila kwethu kudlula ukusebenza kokushisa—sibeka phambili ukuhlanganiswa kwesistimu kanye nokuthembeka kwesikhathi eside, sihlose ukuletha izinhlelo zokupholisa ezisebenza kahle kakhulu nezingabizi kakhulu.

Zizwe ukhululekile ukuxhumana nathi ukuze ufunde kabanzi mayelana nezixazululo zokupholisa zesiteshi esikhulu kanye neziteshi ezincane ezenzelwe izidingo zakho zohlelo lokusebenza!

Isikhathi sokuthunyelwe: Juni-17-2025