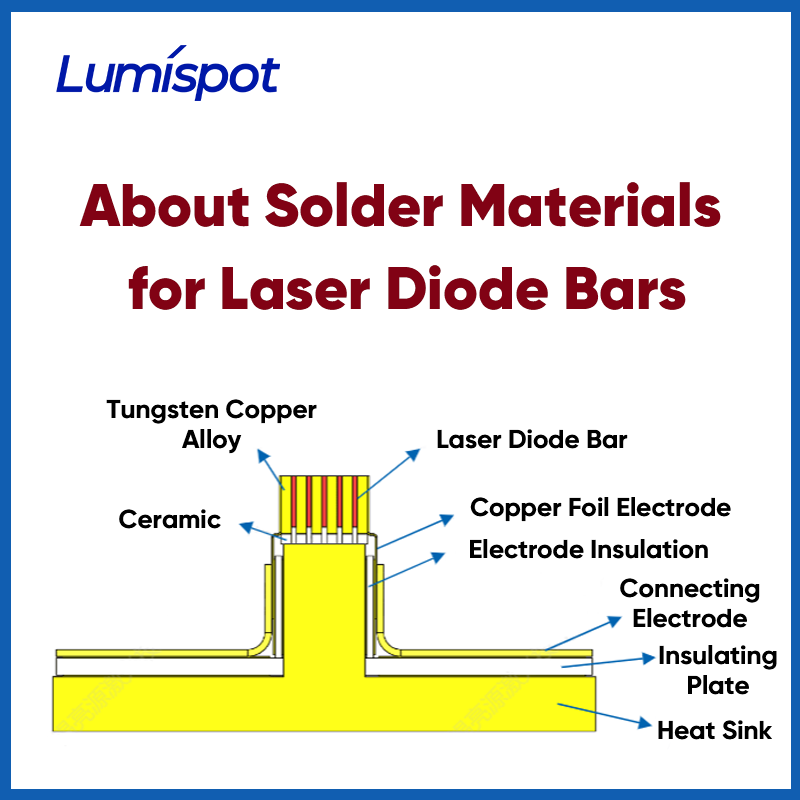

Ekuklanyweni nasekukhiqizweni kwama-laser e-semiconductor anamandla amakhulu, ama-laser diode bars asebenza njengamayunithi ayinhloko akhipha ukukhanya. Ukusebenza kwawo akuxhomekile kuphela kwikhwalithi yangaphakathi yama-laser chips kodwa futhi kakhulu enqubweni yokupakisha. Phakathi kwezingxenye ezahlukahlukene ezihilelekile ekupakisheni, izinto zokufaka i-solder zidlala indima ebalulekile njengesixhumi esishisayo nesikagesi phakathi kwe-chip kanye nesinki yokushisa.

1. Indima Yomshisi Kumabha E-Laser Diode

Amabha e-laser diode ngokuvamile ahlanganisa ama-emitter amaningi, okuholela ekuminyaneni kwamandla aphezulu kanye nezidingo zokuphathwa kokushisa eziqinile. Ukuze kufezwe ukushabalaliswa kokushisa okuphumelelayo kanye nokuqina kwesakhiwo, izinto zokubopha kumele zihlangabezane nalezi zindlela ezilandelayo:

① Ukushisa okuphezulu:

Iqinisekisa ukudluliselwa kokushisa okuphumelelayo kusuka ku-chip ye-laser.

② Ukumanzisa okuhle:

Inikeza ukubopha okuqinile phakathi kwe-chip kanye ne-substrate.

③ Indawo efanele yokuncibilika:

Kuvimbela ukugeleza kabusha noma ukuwohloka ngesikhathi sokucubungula noma ukusebenza okulandelayo.

④ I-coefficient ehambisanayo yokwanda kokushisa (i-CTE):

Kunciphisa ukucindezeleka kokushisa ku-chip.

⑤ Ukumelana nokukhathala okuhle kakhulu:

Kwandisa impilo yesevisi yedivayisi.

2. Izinhlobo Ezivamile Zokushisela Ukupakisha Ibha Ye-Laser

Okulandelayo yizinhlobo ezintathu eziyinhloko zezinto zokufaka ezisetshenziswa kakhulu ekupakisheni imigoqo ye-laser diode:

①I-Alloy ye-Gold-Tin (AuSn)

Izakhiwo:

Ukwakheka kwe-Eutectic okungu-80Au/20Sn okunephuzu lokuncibilika elingu-280°C; ukuhanjiswa okuphezulu kokushisa kanye namandla omshini.

Izinzuzo:

Ukuqina okuhle kakhulu kokushisa okuphezulu, impilo ende yokukhathala kokushisa, okungenazo izinto eziphilayo, ukuthembeka okuphezulu

Izicelo:

Izinhlelo zempi, zezindiza, kanye nezinhlelo ze-laser zezimboni ezisezingeni eliphezulu.

②I-Indium Ehlanzekile (Ngaphakathi)

Izakhiwo:

Izinga lokuncibilika elingu-157°C; lithambile futhi lithambile kakhulu.

Izinzuzo:

Ukusebenza kahle kokujikeleza kokushisa okuphezulu, ukucindezeleka okuphansi kwi-chip, kulungele ukuvikela izakhiwo ezibuthakathaka, kufanelekile ezidingweni zokubopha ezisezingeni eliphansi lokushisa

Imikhawulo:

Ithambekele ekungcolisweni; idinga umoya ongasebenzi ngesikhathi sokucubungula, amandla aphansi omshini; ayilungele ukusetshenziswa komthwalo omningi

③Izinhlelo Zokusonta Ezihlanganisiwe (isb., AuSn + In)

Isakhiwo:

Ngokuvamile, i-AuSn isetshenziswa ngaphansi kwe-chip ukuze inamathele ngokuqinile, kuyilapho i-In isetshenziswa phezulu ukuze kuthuthukiswe ukubhafa kokushisa.

Izinzuzo:

Ihlanganisa ukuthembeka okuphezulu nokukhululeka ekucindezelekeni, ithuthukisa ukuqina kokupakishwa, ivumelana kahle nezimo zokusebenza ezahlukahlukene

3. Umthelela Wekhwalithi Yomthengisi Ekusebenzeni Kwedivayisi

Ukukhethwa kwezinto ezidayisayo kanye nokulawulwa kwenqubo kuthinta kakhulu ukusebenza kwe-electro-optical kanye nokuzinza kwesikhathi eside kwamadivayisi e-laser:

| Isici Sokusoda | Umthelela Kudivayisi |

| Ukufana kwesendlalelo se-solder | Kuthinta ukusatshalaliswa kokushisa kanye nokuvumelana kwamandla okukhanya |

| Isilinganiso esingenalutho | Izikhala eziphakeme ziholela ekumelaneni nokushisa okukhulu kanye nokushisa ngokweqile kwendawo |

| Ubumsulwa be-alloy | Ithonya lokuncibilikisa ukuqina kanye nokusabalala kwe-intermetallic |

| Ukumanzisa kobuso obuphakathi | Inquma amandla okubopha kanye nokuqhuba kokushisa kwe-interface |

Ngaphansi kokusebenza okuqhubekayo kwamandla aphezulu, ngisho namaphutha amancane ekufakweni kwe-solder angaholela ekukhuleni kokushisa, okuholela ekuwohlokeni kokusebenza noma ekuhlulekeni kwedivayisi. Ngakho-ke, ukukhetha i-solder yekhwalithi ephezulu nokusebenzisa izinqubo eziqondile zokunamathisela i-solder kubalulekile ekufinyeleleni ukupakishwa kwe-laser okuthembekile kakhulu.

4. Izitayela Nentuthuko Yesikhathi Esizayo

Njengoba ubuchwepheshe be-laser buqhubeka nokungena ekucutshungulweni kwezimboni, ukuhlinzwa kwezokwelapha, i-LiDAR, kanye neminye imikhakha, izinto zokufaka i-solder zokupakisha i-laser ziyashintsha ngalezi zindlela ezilandelayo:

①Ukushisela okushisa okuphansi:

Ukuhlanganiswa nezinto ezizwela ukushisa

②I-solder engenalo i-lead:

Ukuhlangabezana ne-RoHS kanye neminye imithethonqubo yezemvelo

③Izinto zokusetshenziswa kwe-thermal interface ezisebenza kahle kakhulu (i-TIM):

Ukuze kuncishiswe ukumelana nokushisa

④Ubuchwepheshe bokuthungela izinto ezincane:

Ukusekela i-miniaturization kanye nokuhlanganiswa kwabantu abaningi

5. Isiphetho

Nakuba zincane ngobuningi, izinto zokubopha ziyizixhumi ezibalulekile eziqinisekisa ukusebenza nokuthembeka kwamadivayisi e-laser anamandla aphezulu. Ekupakishweni kwemigoqo ye-laser diode, ukukhetha i-solder efanele nokwenza ngcono inqubo yokubopha kubalulekile ekufezeni ukusebenza okuzinzile kwesikhathi eside.

6. Mayelana Nathi

I-Lumispot izibophezele ekuhlinzekeni amakhasimende ngezingxenye ze-laser zobungcweti nezithembekile kanye nezixazululo zokupakisha. Njengoba sinolwazi oluningi ekukhetheni izinto ze-solder, ukuklama ukuphathwa kokushisa, kanye nokuhlola ukuthembeka, sikholelwa ukuthi yonke imininingwane yokucubungula ivula indlela eya ebuhleni. Ukuze uthole ulwazi olwengeziwe ngobuchwepheshe bokupakisha be-laser obunamandla aphezulu, zizwe ukhululekile ukuxhumana nathi.

Isikhathi sokuthunyelwe: Julayi-07-2025