Bhalisela i-Social Media yethu ukuze uthole okuthunyelwe okusheshayo

Ekukhiqizweni kwemishini ye-laser enembile, ukulawula imvelo kubalulekile. Ezinkampanini ezifana neLumispot Tech, egxile ekukhiqizeni ama-laser asezingeni eliphezulu, ukuqinisekisa ukuthi indawo yokukhiqiza engenalo uthuli akuyona nje indinganiso—kuwukuzibophezela ekhwalithini nasekunelisekeni kwamakhasimende.

Iyini isudi yegumbi lokuhlanza?

Ingubo yegumbi lokuhlanza, eyaziwa nangokuthi isudi yegumbi lokuhlanza, isudi kanogwaja, noma izembozo, iyizingubo ezikhethekile ezenzelwe ukunciphisa ukukhishwa kwezinto ezingcolisayo nezinhlayiya endaweni yegumbi lokuhlanza. Amagumbi okuhlanza ayizindawo ezilawulwayo ezisetshenziswa emikhakheni yesayensi neyezimboni, njengokukhiqiza ama-semiconductor, i-biotechnology, imithi, kanye nezindiza, lapho amazinga aphansi okungcola njengothuli, amagciwane asemoyeni, kanye nezinhlayiya ze-aerosol kubalulekile ekugcineni ikhwalithi nobuqotho bemikhiqizo.

Abasebenzi be-R&D eLumispot Tech

Kungani Kudingeka Izingubo Zokuhlanza:

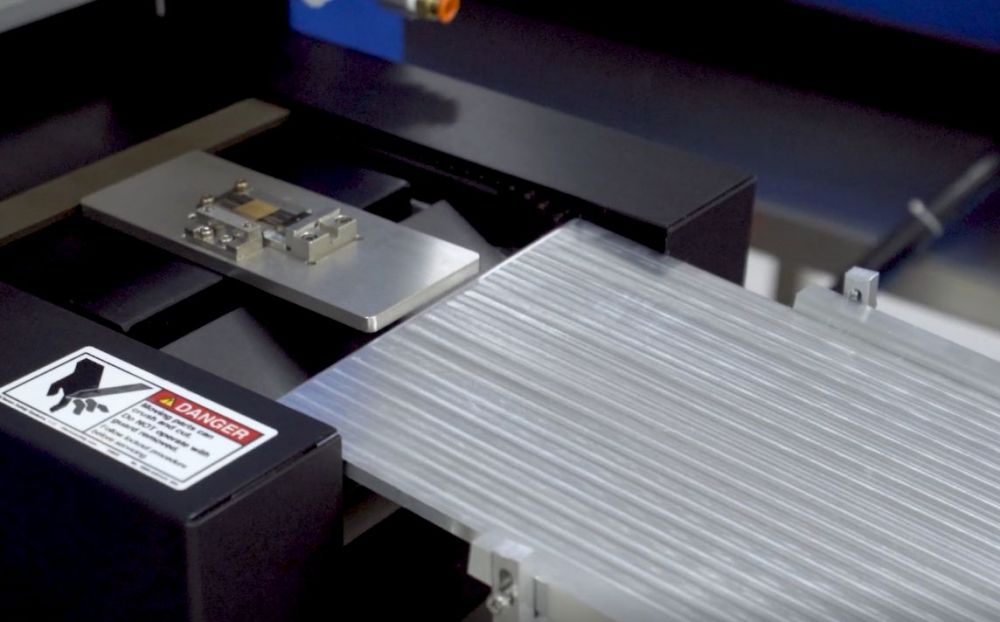

Kusukela yasungulwa ngo-2010, i-Lumispot Tech isebenzise umugqa wokukhiqiza osezingeni eliphezulu, ongenalo uthuli olusezingeni lezimboni ngaphakathi kwesakhiwo sayo esingamamitha-skwele angu-14,000. Bonke abasebenzi abangena endaweni yokukhiqiza kudingeka bagqoke izingubo zokuhlanza ezihambisana nezindinganiso ezijwayelekile. Lo mkhuba ubonisa ukuphathwa kwethu kwekhwalithi okuqinile kanye nokunaka inqubo yokukhiqiza.

Ukubaluleka kwezingubo ezingenalo uthuli eshabhu kubonakala kakhulu kulezi zici ezilandelayo:

Igumbi Lokuhlanza eLumispot Tech

Ukunciphisa Ugesi Ongaguquki

Izindwangu ezikhethekile ezisetshenziswa ezingutsheni zegumbi lokuhlanza zivame ukufaka izintambo eziqhuba umoya ukuvimbela ukwakheka kukagesi ongashintshi, okungalimaza izingxenye ezibucayi ze-elekthronikhi noma kushise izinto ezivuthayo. Ukwakheka kwalezi zingubo kuqinisekisa ukuthi izingozi zokukhishwa kwe-electrostatic discharge (ESD) ziyancishiswa (Chubb, 2008).

Ukulawulwa Kokungcola:

Izingubo zegumbi lokuhlanza zenziwa ngezindwangu ezikhethekile ezivimbela ukuchitheka kwemicu noma izinhlayiya futhi zimelane nokuqongelela kukagesi ongashukumi ongadonsela uthuli. Lokhu kusiza ukugcina amazinga okuhlanzeka aqinile adingekayo emagumbini okuhlanza lapho ngisho nezinhlayiya ezincane zingadala umonakalo omkhulu kuma-microprocessor, ama-microchip, imikhiqizo yemithi, kanye nobunye ubuchwepheshe obubucayi.

Ubuqotho Bomkhiqizo:

Ezinqubweni zokukhiqiza lapho imikhiqizo ibucayi kakhulu ekungcolisweni kwemvelo (njengokukhiqizwa kwe-semiconductor noma ukukhiqizwa kwemithi), izingubo zasendlini yokuhlanza ziyasiza ekuqinisekiseni ukuthi imikhiqizo ikhiqizwa endaweni engenakho ukungcola. Lokhu kubalulekile ekusebenzeni nasekuthembekeni kwezingxenye zobuchwepheshe obuphezulu kanye nokuphepha kwezempilo kwemithi.

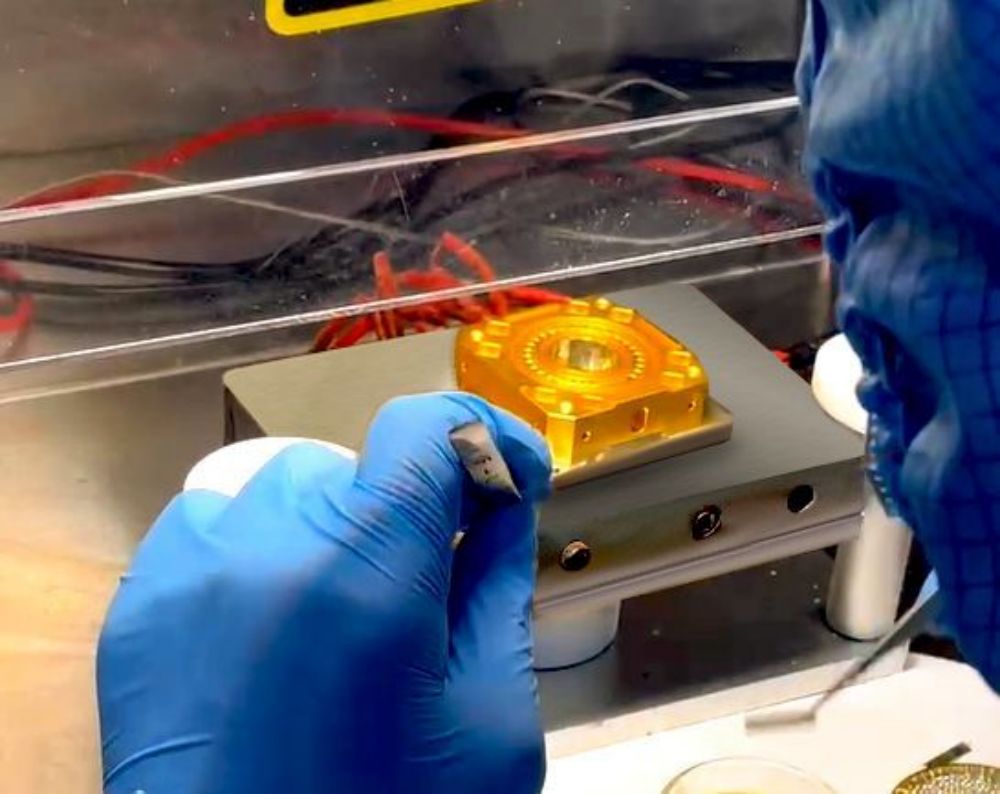

I-Lumispot Tech'sI-Laser Diode Bar ArrayInqubo Yokukhiqiza

Ukuphepha Nokuthobela Imithetho:

Ukusetshenziswa kwezingubo zokuhlanza kuphoqelelwa futhi yizindinganiso ezibekwe yizinhlangano ezifana ne-ISO (International Organisation for Standardization) ehlukanisa amakamelo okuhlanza ngokusekelwe enanini lezinhlayiya ezivunyelwe nge-cubic meter ngayinye yomoya. Izisebenzi ezigumbini zokuhlanza kumele zigqoke lezi zingubo ukuze zihambisane nalezi zindinganiso futhi ziqinisekise kokubili ukuphepha komkhiqizo kanye nezisebenzi, ikakhulukazi lapho zisingatha izinto eziyingozi (Hu & Shiue, 2016).

Ukuhlukaniswa Kwezingubo Zegumbi Lokuhlanza

Amazinga Okuhlukaniswa: Izingubo zokuhlanza zisukela ezigabeni eziphansi njengeKlasi 10000, ezifanele izindawo ezingaqinile kangako, kuya ezigabeni eziphakeme njengeKlasi 10, ezisetshenziswa ezindaweni ezibucayi kakhulu ngenxa yekhono lazo eliphakeme lokulawula ukungcola kwezinhlayiya (Boone, 1998).

Izingubo zekilasi 10 (ISO 3):Lezi zingubo zifanelekela izindawo ezidinga izinga eliphezulu lokuhlanzeka, njengokukhiqizwa kwezinhlelo ze-laser, imicu ye-optical, kanye ne-precision optics. Izingubo ze-Class 10 zivimba ngempumelelo izinhlayiya ezinkulu kune-0.3 micrometer.

Izingubo zeKlasi 100 (ISO 5):Lezi zingubo zisetshenziswa ekukhiqizweni kwezingxenye ze-elekthronikhi, izibonisi zephaneli ezisicaba, kanye neminye imikhiqizo edinga izinga eliphezulu lokuhlanzeka. Izingubo ze-Class 100 zingavimba izinhlayiya ezinkulu kune-0.5 micrometer.

Izingubo zeKlasi 1000 (ISO 6):Lezi zingubo zifanelekela izindawo ezinezidingo zokuhlanzeka okulinganiselwe, njengokukhiqizwa kwezingxenye ezijwayelekile ze-elekthronikhi namadivayisi ezokwelapha.

Izingubo zeKlasi 10,000 (ISO 7):Lezi zingubo zisetshenziswa ezindaweni zezimboni ezijwayelekile ezinezidingo eziphansi zokuhlanzeka.

Izingubo zokuhlanza zivame ukufaka ama-hood, imaski yobuso, amabhuzu, izembozo, namagilavu, konke okwenzelwe ukumboza isikhumba esiveziwe ngangokunokwenzeka nokuvimbela umzimba womuntu, owumthombo omkhulu wokungcola, ukuthi ungangenisi izinhlayiya endaweni elawulwayo.

Ukusetshenziswa Emisebenzini Yokukhiqizwa Kwe-Optical kanye ne-Laser

Ezimweni ezifana nokukhiqizwa kwe-optics kanye ne-laser, izingubo zangasese zivame ukudinga ukuhlangabezana nezindinganiso eziphakeme, ngokuvamile i-Class 100 noma i-Class 10. Lokhu kuqinisekisa ukuphazamiseka okuncane kwezinhlayiya ezingxenyeni ezibucayi ze-optical kanye nezinhlelo ze-laser, okungase kuholele ezinkingeni ezibalulekile zekhwalithi nokusebenza (Stowers, 1999).

Abasebenzi baseLumispot Tech abasebenza kwi-QCWIzinqwaba ze-Annular Laser Diode.

Lezi zingubo zegumbi lokuhlanza zenziwe ngezindwangu ezikhethekile zegumbi lokuhlanza ezingashukumi kahle ezinikeza uthuli oluhle kakhulu kanye nokumelana okungashukumi. Ukwakheka kwalezi zingubo kubalulekile ekugcineni inhlanzeko. Izici ezifana nama-cuff namaqakala aqina kahle, kanye nama-zipper afinyelela ekhola, ziyasetshenziswa ukuze kukhuliswe isithiyo ekungcoleni okungena endaweni ehlanzekile.

Ireferensi

Boone, W. (1998). Ukuhlolwa kwezindwangu zezingubo zegumbi lokuhlanza/ze-ESD: izindlela zokuhlola nemiphumela. Izinqubo ze-Electrical Overstress/Electrostatic Discharge Symposium. 1998 (Cat. No.98TH8347).

Stowers, I. (1999). Imininingwane yokuhlanzeka kwamehlo kanye nokuqinisekiswa kokuhlanzeka. Izinqubo ze-SPIE.

Chubb, J. (2008). Izifundo ze-Tribocharging ezingutsheni zokuhlanza ezihlalwa ngabantu. Ijenali ye-Electrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Ukuqinisekiswa nokusetshenziswa kwesici sabasebenzi sengubo esetshenziswa emakamelweni okuhlanza. Isakhiwo kanye Nemvelo.

Isikhathi sokuthunyelwe: Ephreli-24-2024