Bhalisela i-Social Media yethu ukuze uthole okuthunyelwe okusheshayo

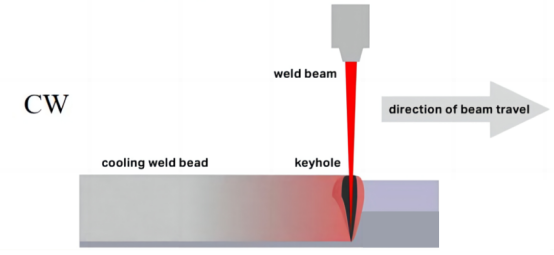

I-Laser Yamagagasi Eqhubekayo

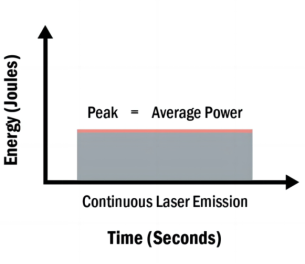

I-CW, isifinyezo se-"Continuous Wave," sibhekisela ezinhlelweni ze-laser ezikwazi ukunikeza ukuphuma kwe-laser okungaphazanyiswa ngesikhathi sokusebenza. Njengoba zibonakala ngekhono lazo lokukhipha i-laser ngokuqhubekayo kuze kube yilapho ukusebenza kuphela, ama-laser e-CW ahlukaniswa ngamandla awo aphansi kanye namandla aphezulu aphakathi uma kuqhathaniswa nezinye izinhlobo zama-laser.

Izinhlelo Zokusebenza Ezibanzi

Ngenxa yesici sawo sokukhipha okuqhubekayo, ama-laser e-CW asetshenziswa kakhulu emikhakheni efana nokusika insimbi nokushisela ithusi ne-aluminium, okwenza abe phakathi kwezinhlobo zama-laser ezivame kakhulu nezisetshenziswa kabanzi. Amandla awo okuletha umphumela wamandla ozinzile nongaguquguquki awenza abe usizo kakhulu kokubili ekucutshungulweni okunembile kanye nasezimweni zokukhiqiza ngobuningi.

Amapharamitha Okulungiswa Kwenqubo

Ukulungisa i-laser ye-CW ukuze kusebenze kahle inqubo kuhilela ukugxila kumapharamitha amaningana abalulekile, kufaka phakathi i-power waveform, inani le-defocus, ububanzi be-beam spot, kanye nesivinini sokucubungula. Ukulungiswa okunembile kwala mapharamitha kubalulekile ekufinyeleleni imiphumela emihle kakhulu yokucubungula, ukuqinisekisa ukusebenza kahle kanye nekhwalithi ekusebenzeni komshini we-laser.

Umdwebo Wamandla E-Laser Oqhubekayo

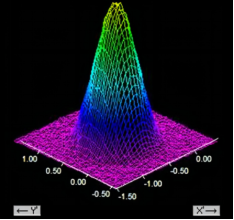

Izici Zokusabalalisa Amandla

Isici esiphawulekayo sama-laser e-CW ukusatshalaliswa kwawo kwamandla e-Gaussian, lapho ukusatshalaliswa kwamandla kwesigaba esiphambene somsebe we-laser kuncipha khona kusukela phakathi kuya ngaphandle ngephethini ye-Gaussian (ukusatshalaliswa okuvamile). Lesi sici sokusatshalaliswa sivumela ama-laser e-CW ukuthi afinyelele ukunemba okuphezulu kakhulu kokugxila kanye nokusebenza kahle kokucubungula, ikakhulukazi ezinhlelweni zokusebenza ezidinga ukufakwa kwamandla agxilile.

Umdwebo Wokusabalalisa Amandla e-CW Laser

Izinzuzo Zokushisela Nge-Laser Okuqhubekayo (CW)

Umbono Wezakhiwo Ezincane

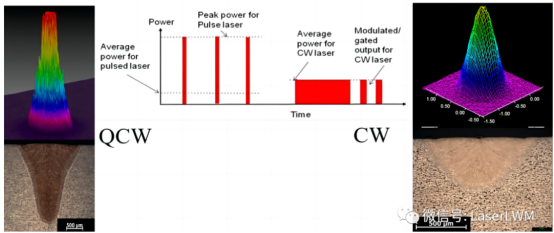

Ukuhlola isakhiwo esincane sezinsimbi kwembula izinzuzo ezihlukile zokushisela nge-laser ye-Continuous Wave (CW) ngaphezu kokushisela nge-Quasi-Continuous Wave (QCW) pulse. Ukushisela nge-QCW pulse, okuvinjelwe umkhawulo wayo wemvamisa, ngokuvamile cishe u-500Hz, kubhekene nokushintshana phakathi kwesilinganiso sokudlulana nokujula kokungena. Isilinganiso sokudlulana esiphansi siphumela ekujuleni okunganele, kanti isilinganiso sokudlulana esiphezulu sivimbela isivinini sokushisela, kunciphisa ukusebenza kahle. Ngokuphambene nalokho, ukushisela nge-laser ye-CW, ngokukhetha ububanzi obufanele be-laser core kanye namakhanda okushisela, kufeza ukushisela okusebenzayo nokuqhubekayo. Le ndlela ithembeke kakhulu ekusetshenzisweni okudinga ubuqotho obukhulu bokuvala.

Ukucatshangelwa Komthelela Wokushisa

Ngokombono womthelela wokushisa, ukushiswa kwe-laser ye-QCW pulse kunenkinga yokugqagqana, okuholela ekushiseni okuphindaphindiwe komthungo wokushiswa. Lokhu kungaletha ukungalingani phakathi kwesakhiwo sensimbi kanye nezinto eziyinhloko, okuhlanganisa ukuhlukahluka kobukhulu bokuhlukana kanye namazinga okupholisa, ngaleyo ndlela kwandisa ingozi yokuqhekeka. Ukushiswa kwe-laser ye-CW, ngakolunye uhlangothi, kugwema le nkinga ngokunikeza inqubo yokushisa efanayo neqhubekayo.

Ukulula Kokulungisa

Ngokuphathelene nokusebenza nokulungiswa, ukushiswa kwe-laser ye-QCW kudinga ukulungiswa okucophelelayo kwamapharamitha amaningana, okuhlanganisa imvamisa yokuphindaphinda kwe-pulse, amandla aphezulu, ububanzi be-pulse, umjikelezo womsebenzi, nokuningi. Ukushiswa kwe-laser ye-CW kwenza inqubo yokulungisa ibe lula, igxile kakhulu ku-waveform, isivinini, amandla, kanye nenani le-defocus, okunciphisa kakhulu ubunzima bokusebenza.

Intuthuko Yezobuchwepheshe Ekushiseni Nge-Laser ye-CW

Nakuba ukushisela nge-laser ye-QCW kwaziwa ngamandla ayo aphezulu kanye nokufakwa okuphansi kokushisa, okuzuzisa ukushisela izingxenye ezizwela ukushisa kanye nezinto ezicijile kakhulu, intuthuko kubuchwepheshe bokushisela nge-laser ye-CW, ikakhulukazi ekusetshenzisweni kwamandla aphezulu (ngokuvamile okungaphezu kwama-watts angu-500) kanye nokushisela okujulile okusekelwe kumphumela we-keyhole, kuye kwandisa kakhulu ububanzi bokusetshenziswa kwayo kanye nokusebenza kahle. Lolu hlobo lwe-laser lufanelekela kakhulu izinto ezijiyile kune-1mm, lufinyelela izilinganiso eziphezulu (ngaphezu kuka-8:1) naphezu kokufakwa kokushisa okuphezulu.

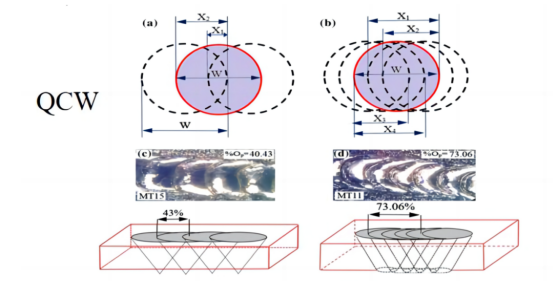

Ukushisela kwe-Laser kwe-Quasi-Continuous Wave (QCW)

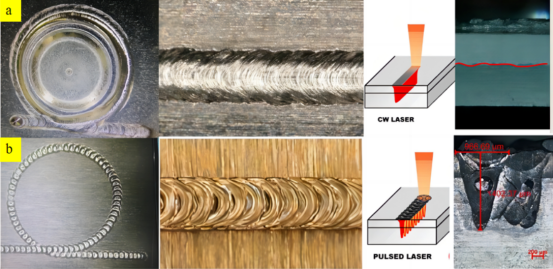

Ukusatshalaliswa Kwamandla Okugxile

I-QCW, emele i-"Quasi-Continuous Wave," imelela ubuchwepheshe be-laser lapho i-laser ikhipha ukukhanya ngendlela engaqhubeki, njengoba kuboniswe esithombeni a. Ngokungafani nokusatshalaliswa kwamandla okufanayo kwama-laser aqhubekayo e-single-mode, ama-laser e-QCW agxilisa amandla awo kakhulu. Lesi sici sinikeza ama-laser e-QCW amandla aphezulu, okuhumusha kube amandla okungena aqinile. Umphumela we-metallurgical ophumelayo ufana nesimo "sezipikili" esinesilinganiso esibalulekile sokujula nobubanzi, okuvumela ama-laser e-QCW ukuthi aphumelele ezinhlelweni zokusebenza ezibandakanya ama-alloy okukhanya okuphezulu, izinto ezizwela ukushisa, kanye ne-micro-welding enembile.

Ukuqina Okuthuthukisiwe Nokuphazamiseka Okuncishisiwe Kwezinsika

Enye yezinzuzo ezivelele zokushisela nge-laser ye-QCW yikhono layo lokunciphisa imiphumela ye-plume yensimbi esilinganisweni sokumuncwa kwezinto, okuholela enqubweni ezinzile kakhudlwana. Ngesikhathi sokusebenzisana kwezinto ze-laser, ukuhwamuka okukhulu kungadala ingxube yomhwamuko wensimbi ne-plasma ngaphezu kwechibi lokuncibilika, okuvame ukubizwa ngokuthi i-plume yensimbi. Le plume ingavikela ubuso bezinto ezibonakalayo ku-laser, okubangela ukulethwa kwamandla okungazinzile kanye neziphazamiso ezifana nokuchitheka, amaphuzu okuqhuma, kanye nemigodi. Kodwa-ke, ukukhishwa okuvamile kwama-laser e-QCW (isb., ukuqhuma okungu-5ms kulandelwe ukumiswa kwe-10ms) kuqinisekisa ukuthi i-laser pulse ngayinye ifinyelela ebusweni bezinto ezibonakalayo ingathinteki yi-plume yensimbi, okuholela enqubweni yokushisela eqinile, enenzuzo ikakhulukazi ekushiseleni kwe-thin-sheet.

Amandla e-Stable Melt Pool

Ukuguquguquka kwechibi lokuncibilika, ikakhulukazi maqondana namandla asebenza embotsheni yokhiye, kubalulekile ekunqumeni ikhwalithi ye-weld. Ama-laser aqhubekayo, ngenxa yokuchayeka kwawo isikhathi eside kanye nezindawo ezinkulu ezithintekile ekushiseni, avame ukudala amachibi amakhulu okuncibilika agcwele insimbi ewuketshezi. Lokhu kungaholela ezifweni ezihambisana namachibi amakhulu okuncibilika, njengokuwa kwembotsheni yokhiye. Ngokuphambene nalokho, amandla agxilile kanye nesikhathi esifushane sokusebenzisana kwe-QCW laser welding kugxila echibini lokuncibilika elizungeze imbotsheni yokhiye, okuholela ekusabalaleni kwamandla okufanayo kanye nokuvama okuphansi kokubhoboka, ukuqhekeka, kanye nokuchitheka.

Indawo Ethinteke Kancane Yokushisa (HAZ)

Ukushisela okuqhubekayo nge-laser kubeka izinto ekushiseni okuqhubekayo, okuholela ekuqhutshweni okukhulu kokushisa kwezinto. Lokhu kungabangela ukuguqulwa kokushisa okungafuneki kanye nokukhubazeka okubangelwa ukucindezeleka ezintweni ezincane. Ama-laser e-QCW, ngokusebenza kwawo ngezikhathi ezithile, avumela izinto ukuthi ziphole, ngaleyo ndlela kuncishiswe indawo ethintekile ekushiseni kanye nokufakwa kokushisa. Lokhu kwenza ukushisela nge-laser ye-QCW kufaneleke kakhulu ezintweni ezincane kanye nalezo eziseduze nezingxenye ezizwela ukushisa.

Amandla Aphezulu Aphezulu

Naphezu kokuba namandla ajwayelekile afanayo nama-laser aqhubekayo, ama-laser e-QCW athola amandla aphezulu kanye nobuningi bamandla, okuholela ekungeneni okujulile kanye namakhono okushisela aqinile. Le nzuzo ibonakala kakhulu ekushiseleni amashidi amancane e-alloy ethusi ne-aluminium. Ngokuphambene nalokho, ama-laser aqhubekayo anamandla ajwayelekile angase ahluleke ukwenza uphawu ebusweni bezinto ngenxa yobuningi bamandla obuphansi, okuholela ekukhanyeni. Ama-laser aqhubekayo anamandla aphezulu, yize ekwazi ukuncibilikisa izinto, angathola ukwanda okukhulu kwesilinganiso sokumuncwa ngemva kokuncibilika, okubangela ukujula kokuncibilika okungalawuleki kanye nokufakwa kokushisa, okungafaneleki ukushisela amashidi amancane futhi kungabangela ukungabikho kokumaka noma ukusha, ukwehluleka ukuhlangabezana nezidingo zenqubo.

Ukuqhathaniswa kwemiphumela yokushisela phakathi kwama-laser e-CW kanye ne-QCW

a. I-Laser Yamagagasi Aqhubekayo (CW):

- Ukubonakala kwesipikili esivalwe nge-laser

- Ukubonakala komthungo wokushisela oqondile

- Umdwebo wesimiso wokukhishwa kwe-laser

- Isigaba esinqamulayo se-longitudinal

b. I-Laser ye-Quasi-Continuous Wave (QCW):

- Ukubonakala kwesipikili esivalwe nge-laser

- Ukubonakala komthungo wokushisela oqondile

- Umdwebo wesimiso wokukhishwa kwe-laser

- Isigaba esinqamulayo se-longitudinal

- * Umthombo: Isihloko sikaWilldong, nge-WeChat Public Account LaserLWM.

- * Isixhumanisi sesihloko sokuqala: https://mp.weixin.qq.com/s/8uCC5jARz3dcgP4zusu-FA.

- Okuqukethwe kwalesi sihloko kuhlinzekwe ngezinjongo zokufunda nokuxhumana kuphela, futhi wonke amalungelo okushicilela angowombhali wokuqala. Uma kuhileleke ukwephulwa kwe-copyright, sicela uxhumane nathi ukuze ususe.

I-QCW Laser evela ku-Lumispot Tech:

I-laser ye-CW:

Isikhathi sokuthunyelwe: Mashi-05-2024