Bhalisela i-Social Media yethu ukuze uthole okuthunyelwe okusheshayo

Isingeniso Sokucubungula Nge-Laser Ekukhiqizeni

Ubuchwepheshe bokucubungula i-laser buthuthuke ngokushesha futhi busetshenziswa kabanzi emikhakheni eyahlukene, njengezindiza, izimoto, izinto zikagesi, nokuningi. Budlala indima ebalulekile ekuthuthukiseni ikhwalithi yomkhiqizo, ukukhiqiza abasebenzi, kanye nokwenza izinto ngokuzenzakalela, ngenkathi kunciphisa ukungcola nokusetshenziswa kwezinto (Gong, 2012).

Ukucutshungulwa kwe-Laser ezintweni zensimbi nezingezona ezensimbi

Ukusetshenziswa okuyinhloko kokucubungula nge-laser eminyakeni eyishumi edlule kube sezinto zensimbi, okuhlanganisa ukusika, ukushisela, kanye nokumboza. Kodwa-ke, insimu iyanda ibe yizinto ezingezona ezensimbi njengezindwangu, ingilazi, ipulasitiki, ama-polymer, kanye ne-ceramics. Ngayinye yalezi zinto ivula amathuba ezimbonini ezahlukahlukene, yize sezivele zinamasu okucubungula asunguliwe (Yumoto et al., 2017).

Izinselele kanye Nokusungula Izinto Ezintsha Ekucubungulweni Kwengilazi Nge-Laser

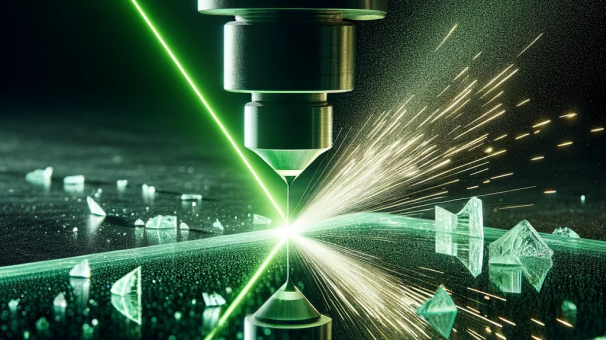

Ingilazi, enezinhlelo zayo ezibanzi ezimbonini ezifana nezimoto, ezokwakha, kanye ne-elekthronikhi, imelela indawo ebalulekile yokucubungula nge-laser. Izindlela zokusika ingilazi zendabuko, ezifaka amathuluzi e-alloy noma edayimane aqinile, zinqunyelwe ukusebenza kahle okuphansi kanye nemiphetho ebukhali. Ngokuphambene nalokho, ukusika nge-laser kunikeza enye indlela esebenza kahle futhi enembile. Lokhu kubonakala kakhulu ezimbonini ezifana nokukhiqiza ama-smartphone, lapho ukusika nge-laser kusetshenziswa khona izembozo zelensi yekhamera kanye nezikrini ezinkulu zokubonisa (Ding et al., 2019).

Ukucutshungulwa Kwe-Laser Kwezinhlobo Zengilazi Ezinenani Eliphezulu

Izinhlobo ezahlukene zengilazi, njengengilazi ekhanyayo, ingilazi ye-quartz, kanye nengilazi ye-sapphire, ziletha izinselele ezihlukile ngenxa yokuthi ziyaphuka kalula. Kodwa-ke, amasu e-laser athuthukile njenge-femtosecond laser etching avumele ukucutshungulwa ngokunembile kwalezi zinto (Sun & Flores, 2010).

Ithonya le-Wavelength Ezinqubweni Zobuchwepheshe be-Laser

Ubude be-laser buyithonya kakhulu inqubo, ikakhulukazi ezintweni ezifana nensimbi yesakhiwo. Ama-laser akhipha ezindaweni ze-infrared ezi-ultraviolet, ezibonakalayo, eziseduze nezikude ahlaziywe ngenxa yamandla awo abalulekile okuncibilikisa nokuhwamuka (Lazov, Angelov, & Teirumnieks, 2019).

Izicelo Ezihlukahlukene Ezisekelwe Kuma-Wavelength

Ukukhetha ubude be-laser abuxhomekeki kodwa kuncike kakhulu ezimpahleni zezinto kanye nomphumela ofiselekayo. Isibonelo, ama-laser e-UV (ane-wavelengths amafushane) amahle kakhulu ekuqopheni ngokunemba kanye nomshini we-micromachining, njengoba engakhiqiza imininingwane emihle kakhulu. Lokhu kuwenza afaneleke kakhulu embonini ye-semiconductor kanye ne-microelectronics. Ngokuphambene nalokho, ama-laser e-infrared asebenza kahle kakhulu ekucubungulweni kwezinto ezijiyile ngenxa yamakhono awo okungena ajulile, okwenza afaneleke kakhulu ezisetshenziswa ezimbonini ezisindayo. (Majumdar & Manna, 2013). Ngokufanayo, ama-laser aluhlaza, avame ukusebenza kubude be-wavelength obungu-532 nm, athola indawo yawo ezinhlelweni ezidinga ukunemba okuphezulu kanye nomthelela omncane wokushisa. Asebenza kahle kakhulu kuma-microelectronics emisebenzini efana nokudweba isekethe, ezisetshenzisweni zezokwelapha zezinqubo ezifana ne-photocoagulation, kanye nasemkhakheni wamandla avuselelekayo wokwenziwa kwamaseli elanga. Ububanzi be-wavelength obuhlukile be-green lasers buwenza afanelekele ukumaka nokuqopha izinto ezahlukahlukene, kufaka phakathi amapulasitiki nezinsimbi, lapho kudingeka khona umehluko omkhulu kanye nomonakalo omncane womphezulu. Lokhu kuvumelana nezimo kwama-laser aluhlaza kugcizelela ukubaluleka kokukhethwa kobude be-wavelength kubuchwepheshe be-laser, kuqinisekisa imiphumela emihle yezinto ezithile kanye nezicelo.

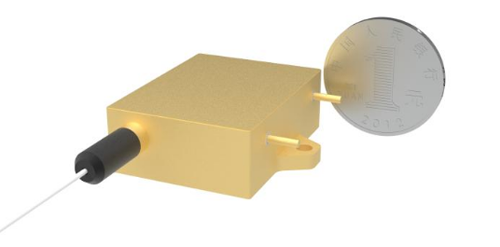

II-laser eluhlaza engu-525nmuhlobo oluthile lobuchwepheshe be-laser olubonakala ngokukhishwa kwalo okuluhlaza okuhlukile kubude bama-nanometer angu-525. Ama-laser aluhlaza kulobu bude bama-wavelength athola ukusetshenziswa ku-retinal photocoagulation, lapho amandla awo aphezulu nokunemba kuzuzisa khona. Angaba usizo futhi ekucutshungulweni kwezinto, ikakhulukazi emikhakheni edinga ukucutshungulwa komthelela wokushisa okunembile nokuncane..Ukuthuthukiswa kwama-diode e-laser aluhlaza ku-c-plane GaN substrate kuya kuma-wavelength amade ku-524–532 nm kuphawula intuthuko enkulu kubuchwepheshe be-laser. Lokhu kuthuthukiswa kubalulekile ekusetshenzisweni okudinga izici ezithile zama-wavelength.

Imithombo Ye-Laser Eqhubekayo Yamagagasi Ne-Modelocked

Imithombo ye-laser eqhubekayo (CW) kanye ne-modellocked quasi-CW laser kuma-wavelength ahlukahlukene njenge-near-infrared (NIR) ku-1064 nm, eluhlaza ku-532 nm, kanye ne-ultraviolet (UV) ku-355 nm iyacatshangelwa kumaseli elanga akhethayo e-emitter. Ama-wavelength ahlukene anemiphumela yokuzivumelanisa nezimo kanye nokusebenza kahle kokukhiqiza (Patel et al., 2011).

Ama-Laser e-Excimer Wezinto Ezine-Wide Band Gap

Ama-laser e-Excimer, asebenza ngobude be-UV, afaneleka ukucubungula izinto ezibanzi njenge-glass kanye ne-carbon fiber-reinforced polymer (CFRP), anikeza ukunemba okuphezulu kanye nomthelela omncane wokushisa (Kobayashi et al., 2017).

Ama-Laser e-Nd:YAG ezinhlelo zokusebenza zezimboni

Ama-laser e-Nd:YAG, anokuguquguquka kwawo ngokwendlela yokulungisa ubude be-wavelength, asetshenziswa ezinhlobonhlobo zezicelo. Amandla awo okusebenza kokubili ku-1064 nm kanye no-532 nm avumela ukuguquguquka ekucubunguleni izinto ezahlukene. Isibonelo, ubude be-wavelength obungu-1064 nm bulungele ukuqoshwa okujulile ezinsimbini, kuyilapho ubude be-wavelength obungu-532 nm buhlinzeka ngokuqoshwa kwendawo esezingeni eliphezulu epulasitikini nasezintweni ezimboziwe. (Moon et al., 1999).

→Imikhiqizo Ehlobene:I-CW Diode-pumped solid-state laser enobude be-wavelength obungu-1064nm

Ukushisela kwe-Laser ye-Fiber enamandla aphezulu

Ama-laser anama-wavelength aseduze no-1000 nm, anekhwalithi enhle ye-beam kanye namandla aphezulu, asetshenziswa ekushiseni nge-laser ye-keyhole yezinsimbi. Lawa ma-laser ashisa futhi ancibilikise izinto ngempumelelo, akhiqize ama-weld asezingeni eliphezulu (Salminen, Piili, & Purtonen, 2010).

Ukuhlanganiswa Kokucubungula Nge-Laser Nobunye Ubuchwepheshe

Ukuhlanganiswa kokucubungula nge-laser nezinye ubuchwepheshe bokukhiqiza, njengokufaka i-cladding kanye nokugaya, kuholele ezinhlelweni zokukhiqiza ezisebenza kahle neziguquguqukayo. Lokhu kuhlanganiswa kuzuzisa kakhulu ezimbonini ezifana nokukhiqiza amathuluzi kanye ne-die kanye nokulungisa injini (Nowotny et al., 2010).

Ukucutshungulwa Kwe-Laser Emasimini Akhulayo

Ukusetshenziswa kobuchwepheshe be-laser kudlulela emikhakheni ekhulayo njengezimboni ze-semiconductor, izibonisi, kanye namafilimu amancane, okunikeza amakhono amasha kanye nokuthuthukisa izakhiwo zezinto, ukunemba komkhiqizo, kanye nokusebenza kwedivayisi (Hwang et al., 2022).

Amathrendi Esikhathi Esizayo Ekucutshungulweni Kwe-Laser

Intuthuko yesikhathi esizayo kubuchwepheshe bokucubungula i-laser igxile emasu amasha okukhiqiza, ukuthuthukisa izimfanelo zomkhiqizo, ubunjiniyela obuhlanganisiwe bezingxenye zezinto eziningi kanye nokuthuthukisa izinzuzo zezomnotho nezenqubo. Lokhu kufaka phakathi ukukhiqizwa okusheshayo kwezakhiwo ezine-porosity elawulwayo nge-laser, ukushisela okuhlanganisiwe, kanye nokusika amashidi ensimbi nge-laser profile (Kukreja et al., 2013).

Ubuchwepheshe bokucubungula i-laser, ngezinhlelo zokusebenza ezahlukahlukene kanye nokusungula izinto ezintsha okuqhubekayo, buyakha ikusasa lokukhiqiza kanye nokucubungula izinto. Ukuguquguquka kwayo kanye nokunemba kwayo kwenza kube ithuluzi elibalulekile ezimbonini ezahlukahlukene, kusunduza imingcele yezindlela zokukhiqiza zendabuko.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). INDLELA YOKULINGANISA KWANGOKUQALA KOBUNZIMA BAMANDLA OBUBALULEKILE EZINQUBENI ZOBUCHWEPHESHE BE-LASER.IMVELO. Ubuchwepheshe. IZINTO EZISETSHENZISWAYO. Izinqubo zeNgqungquthela Yesayensi Nokusebenza Yomhlaba Wonke. Isixhumanisi

UPatel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Ukwakhiwa Okusheshayo Kwamaseli Elanga Akhethiwe Okusebenzisa I-Laser Doping Asebenzisa Imithombo Ye-Laser Eqhubekayo engu-532nm (CW) kanye ne-Modelocked Quasi-CW.Isixhumanisi

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). I-DUV high power lasers processing for glass and CFRP.Isixhumanisi

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Imvamisa ye-intracavity esebenza kahle ephindwe kabili kusuka ku-laser ye-Nd:YAG e-diffusive reflector-type diode side-pumped esebenzisa ikristalu ye-KTP.Isixhumanisi

Salminen, A., Piili, H., & Purtonen, T. (2010). Izici zamandla aphezulu we-fiber laser welding.Izinqubo zeSikhungo Sonjiniyela Bemishini, Ingxenye C: Ijenali Yesayensi Yobunjiniyela Bemishini, 224, 1019-1029.Isixhumanisi

UMajumdar, J., kanye noManna, I. (2013). Isingeniso Sokwenziwa Kwezinto Ezisizwa Nge-Laser.Isixhumanisi

UGong, S. (2012). Uphenyo kanye nokusetshenziswa kobuchwepheshe obuthuthukisiwe bokucubungula i-laser.Isixhumanisi

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Ukuthuthukiswa Kombhede Wokuhlola Wokukhiqiza Nge-Laser kanye Nesizindalwazi Sokucubungula Izinto Ze-Laser.Ukubuyekezwa Kobunjiniyela Be-Laser, 45, 565-570.Isixhumanisi

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Ukuthuthukiswa kobuchwepheshe bokuqapha okungaphakathi kwe-situ bokucubungula i-laser.SCIENTIA SINICA Physica, Mechanica & Astronomica. Isixhumanisi

Sun, H., & Flores, K. (2010). Ukuhlaziywa Kwesakhiwo Sengilazi Enkulu Yensimbi Ecutshungulwa Nge-Laser Esekelwe ku-Zr.Ukuthengiselana Ngezinsimbi Nezinto Ezisetshenziswayo A. Isixhumanisi

UNowotny, S., Muenster, R., Schharek, S., & Beyer, E. (2010). Iseli le-laser elihlanganisiwe lokumbozwa kanye nokugaya nge-laser ehlanganisiwe.Ukuzenzakalela Kokuhlanganisa, 30(1), 36-38.Isixhumanisi

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Amasu Okucubungula Izinto Ze-Laser Ezisafufusa Zezicelo Zezimboni Zesikhathi Esizayo.Isixhumanisi

Hwang, E., Choi, J., & Hong, S. (2022). Izinqubo ezintsha zokuhlanza ezisizwa yi-laser zokukhiqiza okunembile kakhulu, okukhiqiza kakhulu.Isikali Esincane. Isixhumanisi

Isikhathi sokuthunyelwe: Jan-18-2024