| I-Encapsulation Solder ye Izitaki Zebha Ye-Diode Laser | I-AuSn Ipakishwe |

| Ubude Begagasi Eliphakathi | 1064nm |

| Amandla Okukhipha | ≥55W |

| Ukusebenza Kwamanje | ≤30 A |

| I-Voltage Yokusebenza | ≤24V |

| Imodi Yokusebenza | CW |

| Ubude be-Cavity | 900mm |

| Isibuko Sokukhipha | T = 20% |

| Izinga lokushisa lamanzi | 25±3℃ |

Bhalisela i-Social Media yethu ukuze uthole okuthunyelwe okusheshayo

Isidingo samamojula e-laser adonswa yi-CW (Continuous Wave) diode sikhula ngokushesha njengomthombo obalulekile wokupompa wama-laser aqinile. Lawa mamojula anikeza izinzuzo ezihlukile zokuhlangabezana nezidingo ezithile zezicelo ze-laser eziqinile. I-G2 - I-Diode Pump Solid State Laser, umkhiqizo omusha we-CW Diode Pump Series evela ku-LumiSpot Tech, inensimu ebanzi yokusetshenziswa kanye namakhono okusebenza angcono.

Kulesi sihloko, sizofaka okuqukethwe okugxile ekusetshenzisweni komkhiqizo, izici zomkhiqizo, kanye nezinzuzo zomkhiqizo mayelana ne-CW diode pump solid-state laser. Ekupheleni kwesihloko, ngizobonisa umbiko wokuhlolwa kwe-CW DPL ovela ku-Lumispot Tech kanye nezinzuzo zethu ezikhethekile.

Insimu Yesicelo

Ama-laser e-semiconductor anamandla aphezulu asetshenziswa kakhulu njengemithombo yokuphampa yama-laser e-solid-state. Ezisetshenzisweni ezisebenzayo, umthombo wokuphampa i-diode-pumping we-laser ye-semiconductor uyisihluthulelo sokwenza ngcono ubuchwepheshe be-laser e-solid-state ephampuwe yi-laser diode.

Lolu hlobo lwe-laser lusebenzisa i-semiconductor laser enomphumela we-wavelength oqondile esikhundleni se-Krypton noma i-Xenon Lamp yendabuko ukupompa amakristalu. Ngenxa yalokho, le-laser ethuthukisiwe ibizwa ngokuthi i-2ndukukhiqizwa kwe-laser yephampu ye-CW (G2-A), enezici zokusebenza kahle okuphezulu, impilo ende yesevisi, ikhwalithi enhle yemisebe, ukuzinza okuhle, ukuqina kanye nokunciphisa amandla.

Amandla Okupompa Anamandla Aphezulu

Umthombo we-CW Diode Pump unikeza ukuqhuma okukhulu kwesilinganiso samandla okukhanya, okupompa ngempumelelo i-gain medium ku-laser yesimo esiqinile, ukuze kufezwe ukusebenza okuhle kakhulu kwe-laser yesimo esiqinile. Futhi, amandla ayo aphezulu kakhulu (noma amandla ajwayelekile) avumela ububanzi obubanzi bezicelo kuimboni, imithi, kanye nesayensi.

Ukukhanya okuhle kakhulu nokuzinza

Imojula yelaser yokupompa ye-CW semiconductor inekhwalithi evelele yomsebe wokukhanya, enokuqina ngokuzenzekelayo, okubalulekile ukuze kufezwe umphumela wokukhanya we-laser oqondile olawulekayo. Amamojula aklanyelwe ukukhiqiza iphrofayili yomsebe echazwe kahle futhi ezinzile, okuqinisekisa ukupompa okuthembekile nokungaguquguquki kwe-laser yesimo esiqinile. Lesi sici sihlangabezana kahle nezidingo zokusetshenziswa kwe-laser ekucutshungulweni kwezinto zezimboni, ukusika nge-laserkanye ne-R&D.

Ukusebenza Kwamagagasi Okuqhubekayo

Imodi yokusebenza ye-CW ihlanganisa kokubili izinzuzo ze-laser ye-wavelength eqhubekayo kanye ne-Pulsed Laser. Umehluko omkhulu phakathi kwe-CW Laser kanye ne-Pulsed laser ukukhishwa kwamandla.CW I-laser, eyaziwa nangokuthi i-Continuous wave laser, inezici zemodi yokusebenza ezinzile kanye nekhono lokuthumela igagasi eliqhubekayo.

Idizayini Encane Nethembekile

I-CW DPL ingafakwa kalula ku-currenti-laser yesimo esiqinilekuye ngomklamo kanye nesakhiwo esincane. Ukwakhiwa kwazo okuqinile kanye nezingxenye zekhwalithi ephezulu kuqinisekisa ukuthembeka kwesikhathi eside, kunciphisa izindleko zokungasebenzi kanye nokugcinwa, okubaluleke kakhulu ekukhiqizweni kwezimboni kanye nezinqubo zezokwelapha.

Isidingo Semakethe Sochungechunge lwe-DPL - Amathuba Emakethe Akhulayo

Njengoba isidingo sama-laser e-solid-state siqhubeka nokukhula kuzo zonke izimboni ezahlukene, nesidingo semithombo yokupompa esebenza kahle kakhulu njengamamojula e-laser e-CW diode-pumped siyakhula. Izimboni ezifana nokukhiqiza, ezempilo, ezokuvikela, kanye nocwaningo lwesayensi zithembele kuma-laser e-solid-state ukuze zisetshenziswe ngokunemba.

Ngamafuphi, njengomthombo wokupompa we-diode we-laser yesimo esiqinile, izici zemikhiqizo: ikhono lokupompa elinamandla aphezulu, imodi yokusebenza ye-CW, ikhwalithi yogongolo oluhle kakhulu kanye nokuqina, kanye nomklamo ohlelekile kahle, kwandisa isidingo semakethe kula mamojula we-laser. Njengomhlinzeki, i-Lumispot Tech iphinde ifake umzamo omkhulu ekwenzeni ngcono ukusebenza kanye nobuchwepheshe obusetshenziswa ochungechungeni lwe-DPL.

Iqoqo Lomkhiqizo Le-G2-A DPL Elivela Ku-Lumispot Tech

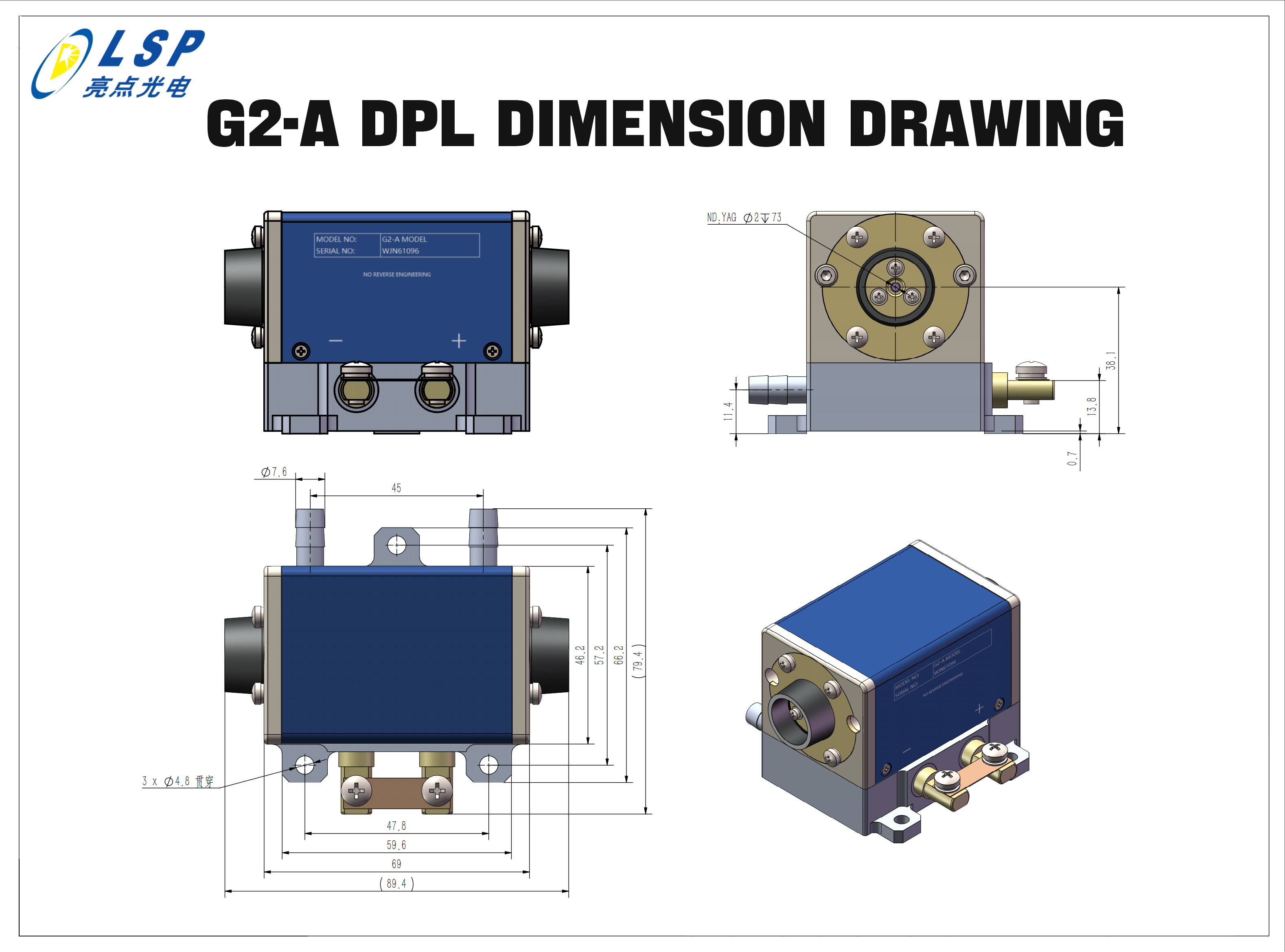

Iqoqo ngalinye lemikhiqizo liqukethe amaqembu amathathu amamojula e-array abekwe ngokuvundlile, iqembu ngalinye lamamojula e-Horizontal Stacked Array anamandla okupompa angaba ngu-100W@25A, kanye namandla okupompa aphelele angu-300W@25A.

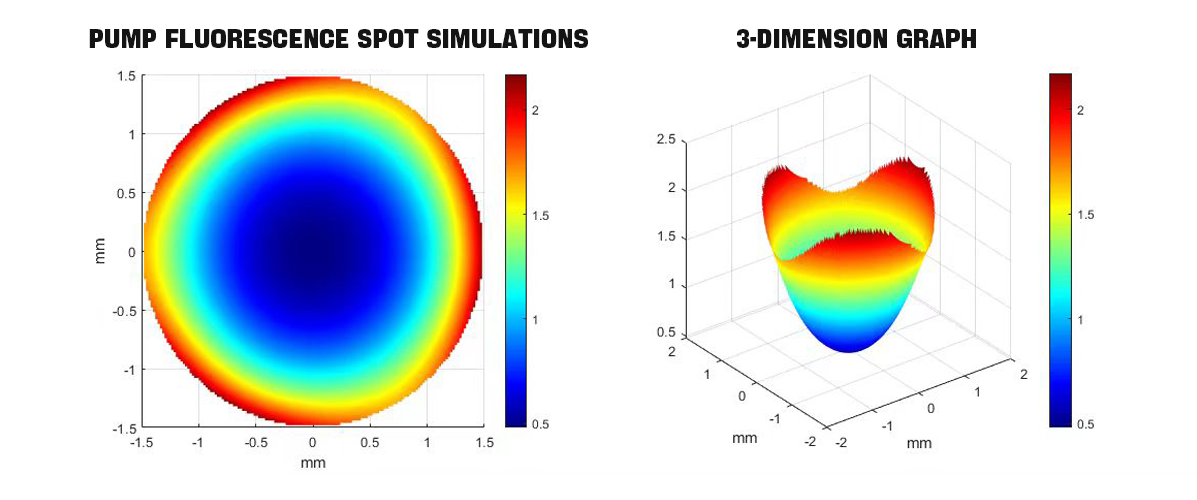

Indawo yokukhazimula kwephampu ye-G2-A iboniswe ngezansi:

Idatha Eyinhloko Yobuchwepheshe Ye-G2-A Diode Pump Solid State Laser:

Amandla Ethu Kubuchwepheshe

1. Ubuchwepheshe Bokuphathwa Kokushisa Okwesikhashana

Ama-laser e-solid-state adonswa yi-semiconductor asetshenziswa kabanzi kwizicelo zamagagasi aqhubekayo (CW) anokukhishwa kwamandla okuphezulu kanye nezicelo zamagagasi aqhubekayo (CW) anokukhishwa kwamandla okumaphakathi okuphezulu. Kula ma-laser, ukuphakama kwesinki yokushisa kanye nebanga eliphakathi kwama-chips (okungukuthi, ukujiya kwe-substrate kanye ne-chip) kuthinta kakhulu ikhono lokusabalalisa ukushisa lomkhiqizo. Ibanga elikhulu le-chip-to-chip liphumela ekushabalaleni okungcono kokushisa kodwa landisa ivolumu yomkhiqizo. Ngokuphambene nalokho, uma isikhala se-chip sincishisiwe, usayizi womkhiqizo uzoncishiswa, kodwa ikhono lokusabalalisa ukushisa lomkhiqizo lingase linganele. Ukusebenzisa ivolumu encane kakhulu ukuklama i-laser efanelekile ye-solid-state edonswa yi-semiconductor ehlangabezana nezidingo zokusabalalisa ukushisa kuwumsebenzi onzima ekwakhiweni.

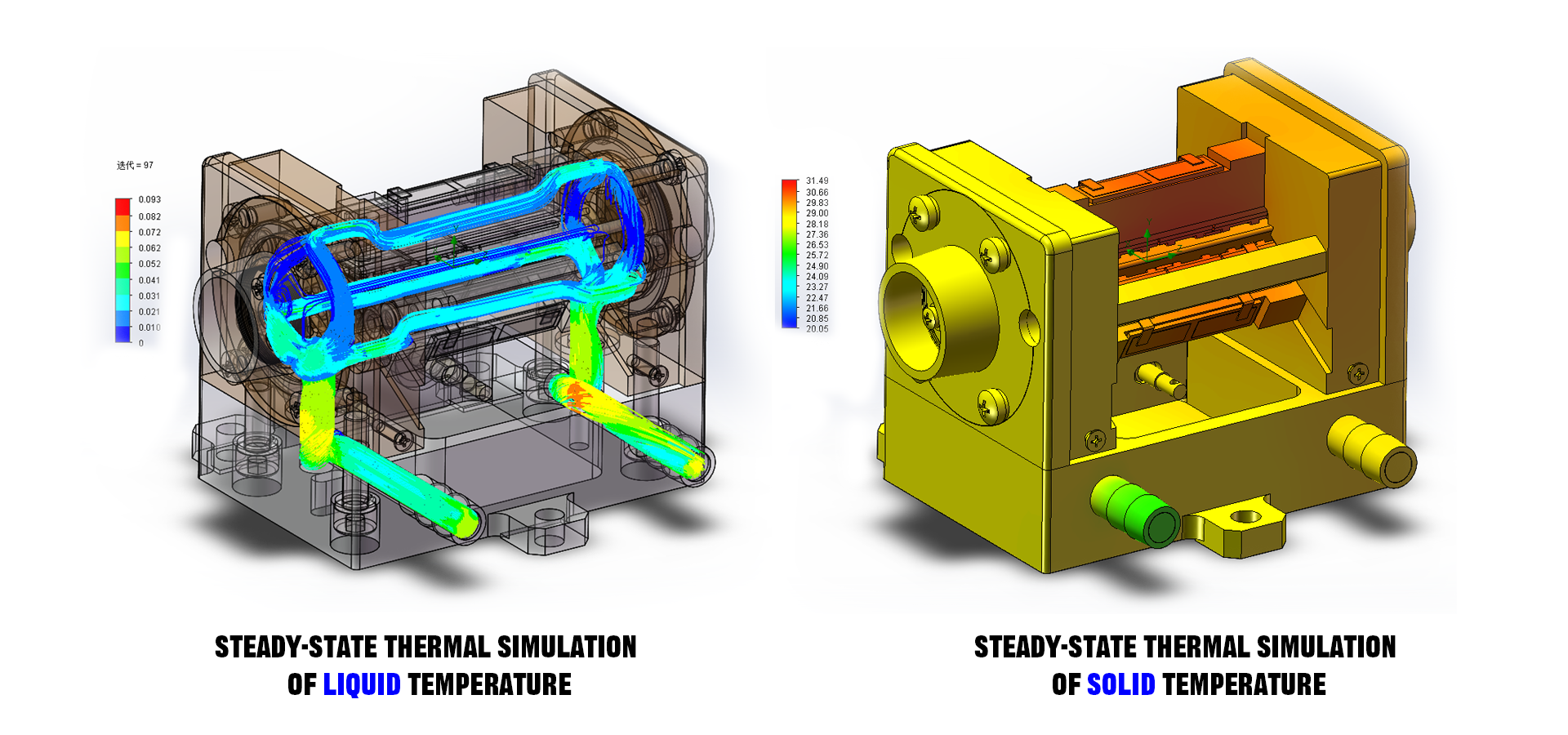

Igrafu Yokulingisa Ukushisa Okuzinzile

I-Lumispot Tech isebenzisa indlela ye-finite element ukulingisa nokubala insimu yokushisa yedivayisi. Inhlanganisela yokulingisa ukushisa okuqinile kanye nokulingisa ukushisa koketshezi isetshenziselwa ukulingisa ukushisa. Ezimweni zokusebenza eziqhubekayo, njengoba kuboniswe esithombeni esingezansi: umkhiqizo uhlongozwa ukuthi ube nesikhala se-chip esifanele kanye nokuhlelwa ngaphansi kwezimo zokulingisa ukushisa okuqinile kanye nokulinganisa ukushisa okuzinzile. Ngaphansi kwalesi sikhala kanye nesakhiwo, umkhiqizo unekhono elihle lokushabalalisa ukushisa, izinga lokushisa eliphansi, kanye nesici esincane kakhulu.

2.I-AuSn solderinqubo yokufakwa kwe-encapsulation

I-Lumispot Tech isebenzisa indlela yokupakisha esebenzisa i-AnSn solder esikhundleni se-indium solder yendabuko ukuze ibhekane nezinkinga ezihlobene nokukhathala kokushisa, ukufuduka kwe-electromigration, kanye nokufuduka kukagesi-okushisa okubangelwa yi-indium solder. Ngokusebenzisa i-AuSn solder, inkampani yethu ihlose ukuthuthukisa ukuthembeka komkhiqizo kanye nokuphila isikhathi eside. Lokhu kushintshaniswa kwenziwa ngenkathi kuqinisekiswa izikhala ezihlala njalo ze-bar stacks, okuqhubeka nokufaka isandla ekuthuthukisweni kokuthembeka komkhiqizo kanye nokuphila kwesikhathi.

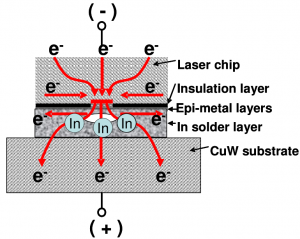

Kubuchwepheshe bokupakisha be-laser enamandla amakhulu e-semiconductor pumped solid-state, insimbi ye-indium (In) iye yamukelwa njengezinto zokushisela ngabakhiqizi bamazwe ngamazwe ngenxa yezinzuzo zayo ze-low melting point, i-low welding stress, ukusebenza okulula, kanye nokuguqulwa okuhle kwepulasitiki kanye nokungena. Kodwa-ke, kuma-laser e-semiconductor pumped solid state ngaphansi kwezimo zokusebenza okuqhubekayo, i-alternating stress izobangela ukukhathala kwengcindezi kwengqimba yokushisela ye-indium, okuzoholela ekwehlulekeni komkhiqizo. Ikakhulukazi emazingeni okushisa aphezulu naphansi kanye nobubanzi obude be-pulse, izinga lokuhluleka kwe-indium welding lisobala kakhulu.

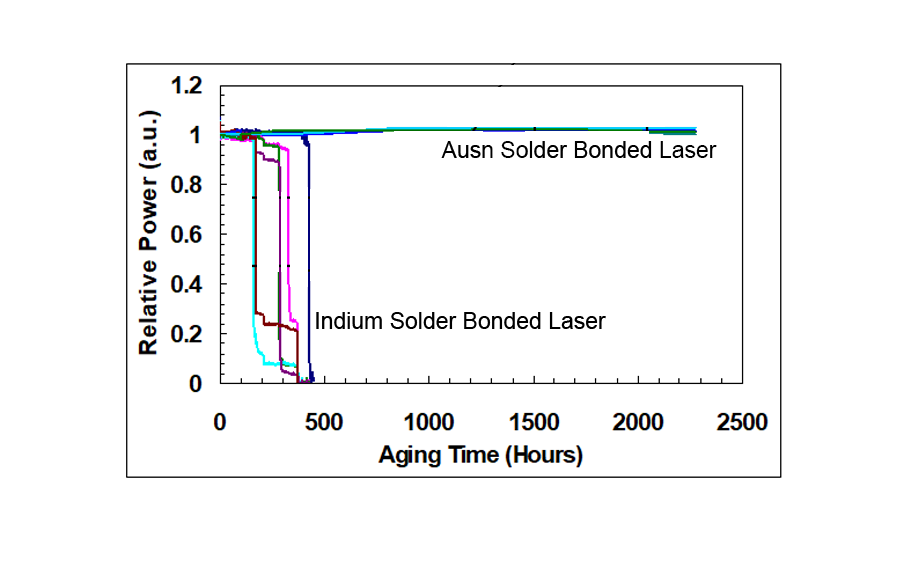

Ukuqhathaniswa kokuhlolwa kokuphila okusheshayo kwama-laser ngamaphakheji ahlukene e-solder

Ngemva kwamahora angu-600 okuguga, yonke imikhiqizo ehlanganiswe nge-indium solder iyahluleka; kuyilapho imikhiqizo ehlanganiswe nge-gold tin isebenza amahora angaphezu kuka-2,000 ngaphandle kokushintsha kwamandla; okubonisa izinzuzo ze-AuSn encapsulation.

Ukuze kuthuthukiswe ukuthembeka kwama-laser e-semiconductor anamandla aphezulu ngenkathi kugcinwa ukuvumelana kwezinkomba zokusebenza ezahlukahlukene, i-Lumispot Tech isebenzisa i-Hard Solder (AuSn) njengohlobo olusha lwezinto zokupakisha. Ukusetshenziswa kwe-coefficient yezinto zokwakha ezihambisana ne-thermal expansion matched substrate (CTE-Matched Submount), ukukhululwa okuphumelelayo kokucindezeleka kokushisa, ikhambi elihle ezinkingeni zobuchwepheshe ezingase zihlangane nazo ekulungiseleleni i-hard solder. Isimo esidingekayo sokuthi izinto ze-substrate (submount) zikwazi ukusondezwa ku-chip ye-semiconductor i-surface metallization. I-surface metallization ukwakheka kwengqimba yesithiyo sokusabalalisa kanye nengqimba yokungena kwe-solder ebusweni bezinto ze-substrate.

Umdwebo weskimu wendlela yokufuduka kwe-electromigration ye-laser efakwe ku-indium solder

Ukuze kuthuthukiswe ukuthembeka kwama-laser e-semiconductor anamandla aphezulu ngenkathi kugcinwa ukuvumelana kwezinkomba zokusebenza ezahlukahlukene, i-Lumispot Tech isebenzisa i-Hard Solder (AuSn) njengohlobo olusha lwezinto zokupakisha. Ukusetshenziswa kwe-coefficient yezinto zokwakha ezihambisana ne-thermal expansion matched substrate (CTE-Matched Submount), ukukhululwa okuphumelelayo kokucindezeleka kokushisa, ikhambi elihle ezinkingeni zobuchwepheshe ezingase zihlangane nazo ekulungiseleleni i-hard solder. Isimo esidingekayo sokuthi izinto ze-substrate (submount) zikwazi ukusondezwa ku-chip ye-semiconductor i-surface metallization. I-surface metallization ukwakheka kwengqimba yesithiyo sokusabalalisa kanye nengqimba yokungena kwe-solder ebusweni bezinto ze-substrate.

Inhloso yayo ngakolunye uhlangothi ukuvimba i-solder ekusakazweni kwezinto ze-substrate, ngakolunye uhlangothi ukuqinisa i-solder ngekhono lokushisela izinto ze-substrate, ukuvimbela ungqimba lwe-solder lwe-cavity. I-surface metallization ingavimbela futhi ukushiswa komhlaba kwezinto ze-substrate kanye nokungena komswakama, kunciphise ukumelana kokuthintana enkambisweni yokushisela, ngaleyo ndlela kuthuthukiswe amandla okushisela kanye nokuthembeka komkhiqizo. Ukusetshenziswa kwe-hard solder AuSn njengezinto zokushisela zama-laser aqinile aphethwe yi-semiconductor kungagwema ngempumelelo ukukhathala kwe-indium stress, i-oxidation kanye nokufuduka kwe-electro-thermal kanye nezinye izinkinga, kuthuthukise kakhulu ukuthembeka kwama-laser e-semiconductor kanye nokuphila kwenkonzo ye-laser. Ukusetshenziswa kobuchwepheshe be-gold-tin encapsulation kunganqoba izinkinga zokufuduka kwe-electrothermal kanye nokufuduka kwe-electrothermal kwe-indium solder.

Isixazululo Esivela Ku-Lumispot Tech

Kuma-laser aqhubekayo noma aqhutshwa ngamandla, ukushisa okukhiqizwa ukumuncwa kwemisebe yephampu yi-laser medium kanye nokupholisa kwangaphandle kwe-medium kuholela ekusabalaleni kokushisa okungalingani ngaphakathi kwe-laser medium, okuholela ekushintsheni kwezinga lokushisa, okubangela izinguquko ku-refractive index ye-medium bese kukhiqiza imiphumela ehlukahlukene yokushisa. Ukufakwa kwe-thermal ngaphakathi kwe-gain medium kuholela kumphumela we-thermal lensing kanye nomphumela we-birefringence obangelwa ukushisa, okhiqiza ukulahlekelwa okuthile ohlelweni lwe-laser, okuthinta ukuzinza kwe-laser emgodini kanye nekhwalithi yomsebe wokukhipha. Kuhlelo lwe-laser olusebenza njalo, ukucindezeleka kokushisa ku-gain medium kuyashintsha njengoba amandla ephampu ekhuphuka. Imiphumela ehlukahlukene yokushisa ohlelweni ithinta kakhulu lonke uhlelo lwe-laser ukuthola ikhwalithi engcono yomsebe kanye namandla aphezulu okukhipha, okungenye yezinkinga okufanele zixazululwe. Indlela yokuvimbela nokunciphisa ngempumelelo umphumela wokushisa wamakristalu enkambisweni yokusebenza, ososayensi bebelokhu bekhathazekile isikhathi eside, sekungenye yezindawo ezishisayo zocwaningo zamanje.

I-laser ye-Nd:YAG ene-lens cavity yokushisa

Kuphrojekthi yokuthuthukisa ama-laser e-Nd:YAG anamandla aphezulu e-LD-pumped Nd:YAG, ama-laser e-Nd:YAG ane-thermal lensing cavity axazululiwe, ukuze i-module ikwazi ukuthola amandla aphezulu ngenkathi ithola ikhwalithi ephezulu ye-beam.

Kuphrojekthi yokuthuthukisa i-laser ye-LD-pumped Nd:YAG enamandla amakhulu, i-Lumispot Tech ithuthukise i-module ye-G2-A, exazulula kakhulu inkinga yamandla aphansi ngenxa yemigodi equkethe ilensi yokushisa, okuvumela i-module ukuthi ithole amandla aphezulu ngekhwalithi ephezulu ye-beam.

Isikhathi sokuthunyelwe: Julayi-24-2023